PU, or polyurethane, is a material that is often used in the insole industry. The best thing about it is that it balances comfort, durability and functionality, which is why a lot of brands choose it for insoles that are mid-to-high-end.

What makes PU comfort insoles special is their ability to balance cushioning and softness by adjusting the foam density and structural design. For example, PU insoles can be as good as Poron at absorbing shocks, which reduces the impact of walking. In terms of softness, the foot feel can be quite close to that of slow-rebound memory foam – comfortable and supportive at the same time.

PU insoles are comfortable, durable and non-slip. This makes them suitable for many different uses, from everyday wear to sports and even work shoes. These days, people care more about comfort and foot health, so PU insoles are a popular choice for brands that want to improve their shoes.

The key features of PU comfort insoles

1. Cushioning and softness

The adjustable foam density of PU material makes the insole provide a soft foot feeling and good cushioning performance at the same time. Low-density PU insoles (about 0.05-0.30 g/cm³) are soft and comfortable, suitable for prolonged standing or daily wear, which can effectively reduce pressure on feet and improve comfort.

2. High elasticity, suitable for sports needs

By adjusting the foam density and structural design of PU, the insole can achieve high elasticity and stable support performance. High density PU insole (about 0.30-0.60 g/cm³) provides stronger support and elasticity, suitable for low and medium intensity sports scenarios such as jogging, walking, fitness, etc., helping to improve sports performance and reduce foot fatigue.

3. Superior durability to meet emerging market demand

PU material has good abrasion resistance and durability, which can withstand the wear and tear of daily use and extend the service life of the insoles. In emerging markets such as South America, such as Brazil and Argentina, consumers have clear requirements for durability and price sensitivity. PU insoles perform well in these markets, meeting consumer demand for value-for-money products.

4. Cost-effectiveness and market acceptance

As a mature manufacturing product, PU insoles have demonstrated a clear advantage in purchase cost with the benefit of mass production. Compared to traditional memory foam, latex and TPE insoles, PU insoles have a better balance of performance, durability and cost. Meanwhile, PU insoles have been widely recognised in the end-user market and have become the first choice of many brands and consumers.

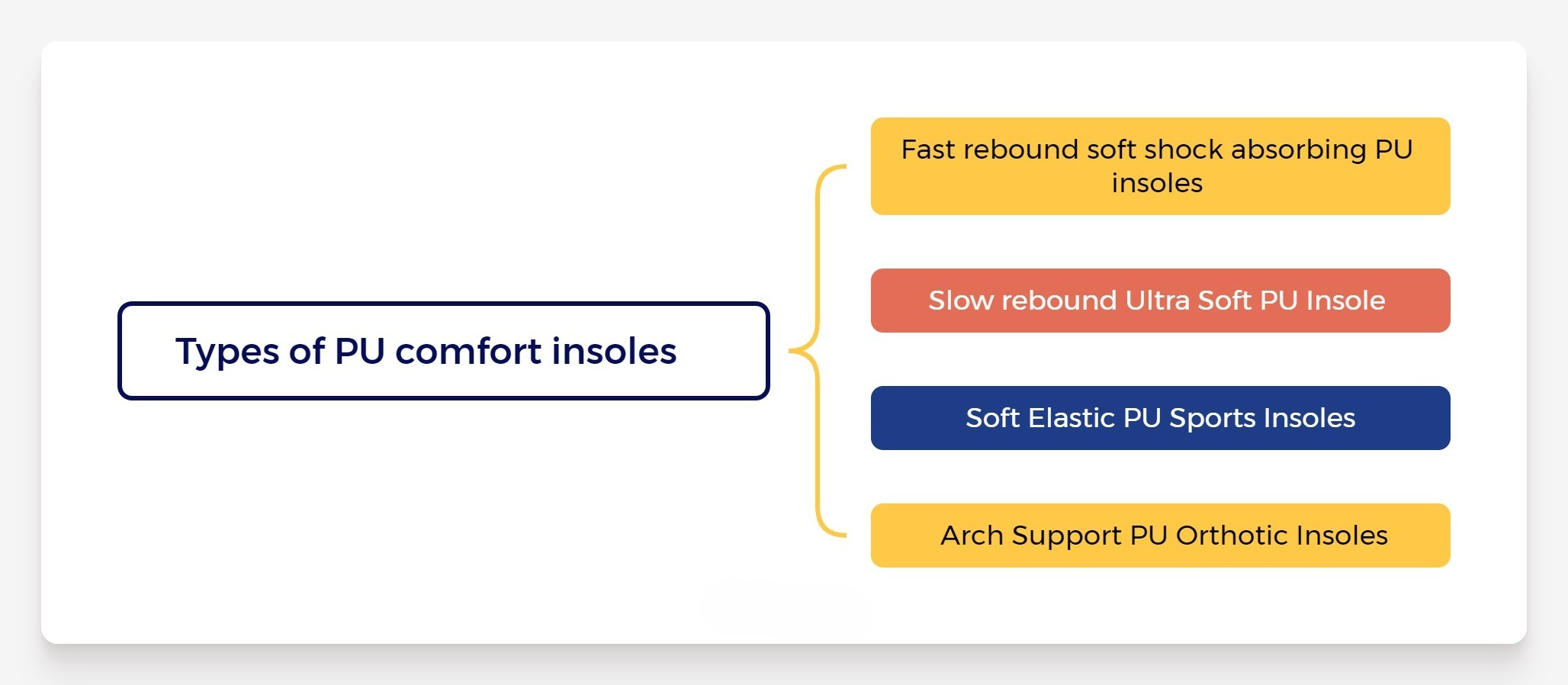

The distinction between types of PU comfort insoles

The adjustability of PU material enables it to meet the needs of different users, The following are several common types of PU comfort insoles.

1. Fast rebound soft shock absorbing PU insoles

These insoles are made of low density PU material with good softness and cushioning performance, suitable for daily standing, walking and light exercise. Commonly used in work shoes (work inlay) to provide comfortable support for professional people who need to stand for long periods of time.

2. Slow rebound Ultra Soft PU Insole

A special PU foam process is used to create a slow rebound insole with a feel similar to memory foam, providing the ultimate softness experience. Suitable for users who need to stand for long periods of time, such as retail and medical professionals.

3. Soft Elastic PU Sports Insoles

Made of high density PU material, it provides excellent elasticity and support and is suitable for medium intensity sports, especially jumping sports such as basketball. It can effectively absorb shock and reduce foot fatigue.

4. Arch Support PU Orthotic Insoles

Combining PU material and arch support design, it helps to improve foot posture, relieve plantar fasciitis and other problems, and improve foot health. Suitable for users who have foot problems or need extra support.

Currently, PU comfort insoles with fast rebound and arch support are particularly popular in the global market.

For example, Dr Scholl's popular 'Work All-Day Superior Comfort Insoles' feature a quick-rebound design and are popular with professionals who have to stand for long periods of time. In addition, ‘the Plantar Fasciitis Pain Relief Orthotics line' features arch support to relieve foot discomfort and increase comfort.

The success of these products further demonstrates the superior performance of PU insoles in terms of comfort, support and durability, meeting the diverse needs of different users.

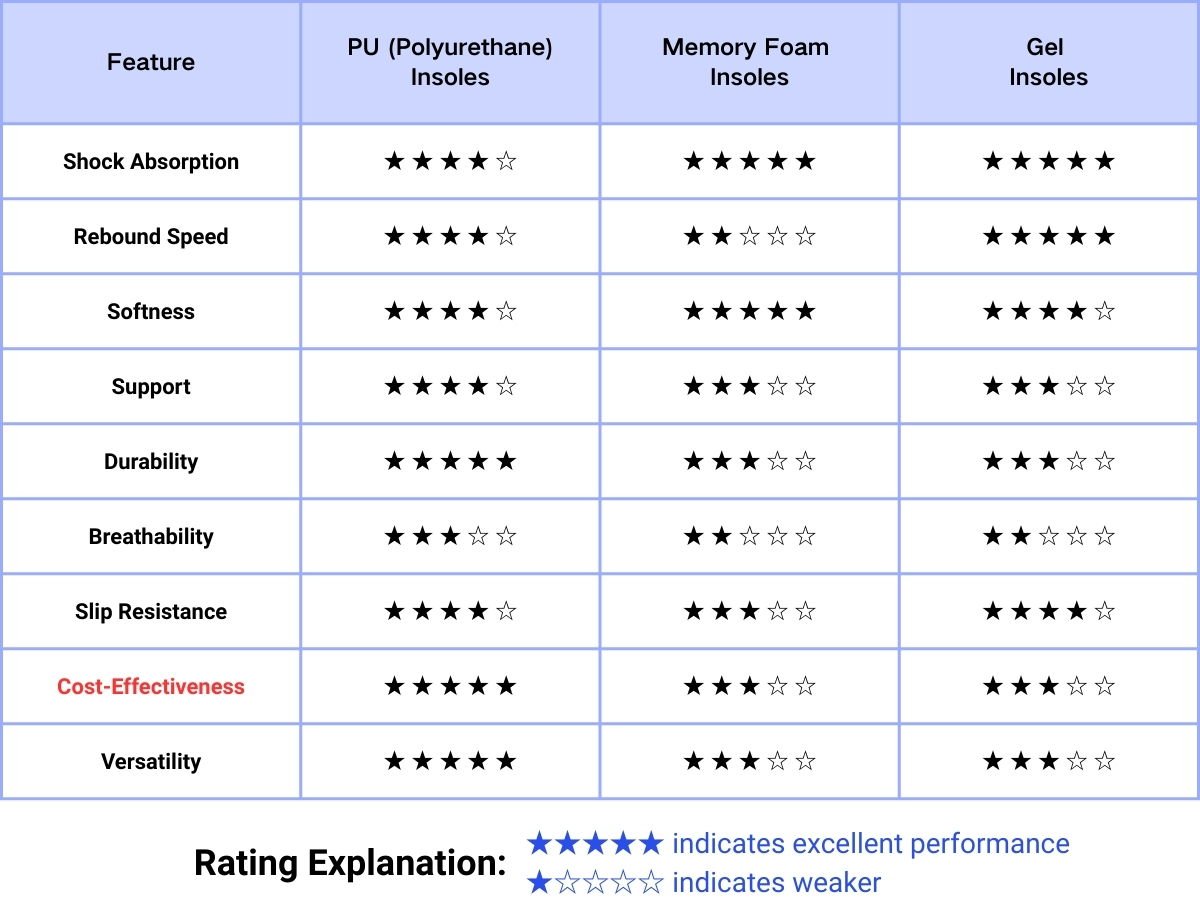

PU VS Memory Foam & GEL

When choosing a comfortable insole, the choice of material is crucial. PU (polyurethane), memory foam and gel are three common insole materials on the market, each of which has unique physical properties and application scenarios. Below is a detailed comparison of these three materials to help you make an informed choice.

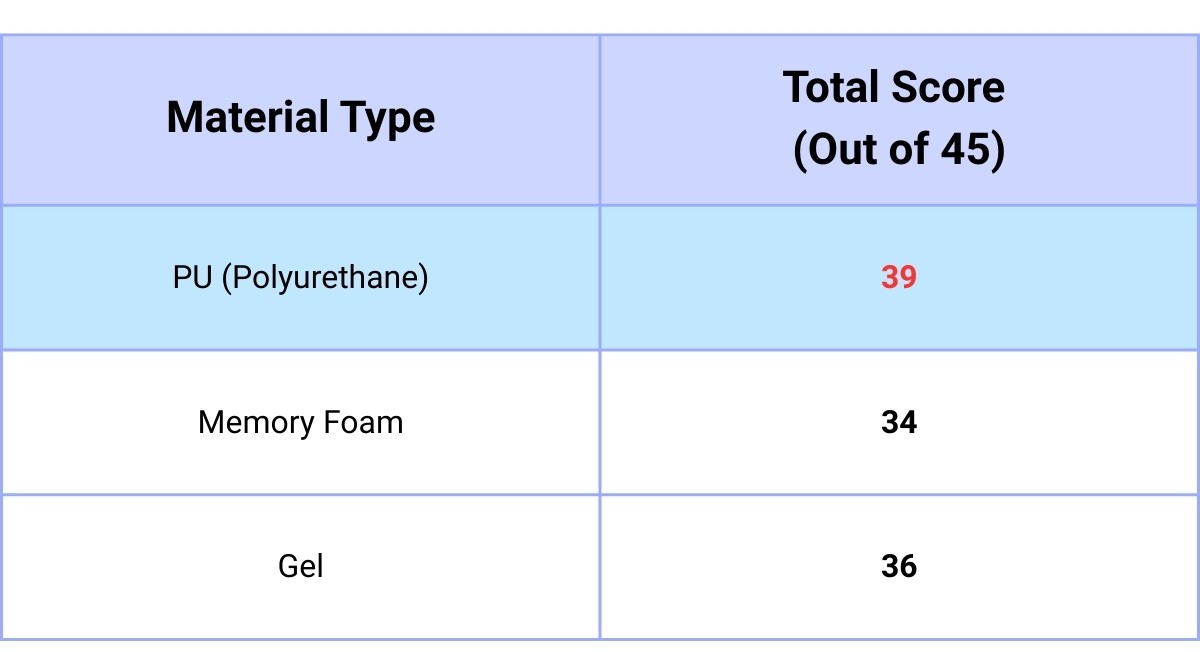

Overall Evaluation Summary

Summary:

According to the evaluation results, PU insoles excel in terms of cushioning, support, durability and cost-effectiveness for a wide range of use scenarios. In contrast, memory foam insoles offer ultimate comfort and are suitable for prolonged static standing scenarios, while gel insoles excel in high-impact activities and provide superior cushioning. Choosing the right insole material for your specific needs will greatly enhance your wearing experience.

Manufacturing Process of PU Comfort Insoles

The manufacturing process of polyurethane (PU) insoles is mainly divided into two types: foaming process and non-foaming process. Each process has its own unique process and application scenarios to meet the needs of different consumers for comfort, support and durability.

1. PU foam insole manufacturing process

PU foam insole usually adopts high-pressure or low-pressure foaming technology, in which polyurethane raw materials are injected into moulds through special equipment, and after a chemical reaction, insoles with elasticity and cushioning properties are formed. This process is suitable for mass production and can achieve product consistency and high efficiency.

The manufacturing process includes:

Raw material preparation: Polyether polyol (polyol) and isocyanate (isocyanate) are mixed proportionally, and catalysts, blowing agents, and other additives are added.

Mixing and injection: The mixture is injected into the preheated mould using a foaming machine.

Foaming & Curing: A chemical reaction takes place in the mould to form a foam structure, which is cured at a certain temperature.

Demoulding & Finishing: The moulded insole is removed for finishing and quality control.

The insoles produced by this process have good cushioning performance and comfort and are suitable for many types of footwear, such as sports and work shoes.

2. How we make PU non-foaming insoles

The non-foaming process uses something called injection molding technology. This is where PU raw materials are put straight into the mold. Then the mold is heated and pressed to make the insoles. This process is great for making insoles with complex structures that need to be very precise, like orthopedic insoles.

The production process includes :

The following steps: Preparing the raw materials. Prepare the PU raw material to make sure it is the right consistency for injection molding.

Injection moulding is a process where a liquid material (like a plastic) is pumped into a mold, which is then closed and heated to harden the material. The raw material is put into the mould and heated and pressed to shape it.

Cooling and demolding: this is when the insoles are cooled in the mould, then removed to be processed further.

The insoles made by this process are very precise and offer great support. They are perfect for insole products that need to have special functions. Continue reading to find out more.

In the last article, we explained how PU foam and non-foam insoles are made. The way they are made depends on what people want and how the products are sold. This means that manufacturers can choose the best way to make different products to suit different customers.

For example, PU foam insoles are great for sports and work shoes because they're really comfortable and cushion your step. On the other hand, non-foamed insoles are better for products like orthopedic insoles because they have complex structures and need to be really precise. By choosing the right way to make their products, manufacturers can effectively meet the needs of different markets and improve how competitive their products are.

About RUNTONG

RUNTONG is a professional company that provides insoles made of PU (polyurethane), a type of plastic. It is based in China and specialises in shoe and foot care. PU comfort insoles are one of our main products and are very popular all over the world.

We promise to provide medium and large customers with a full range of services, from planning products to delivering them. This means that each product will meet what the market wants and what consumers expect.

We offer the following services:

Market research and planning the product We look closely at market trends and use data to make recommendations about products to help our clients.

We update our style every year and use the latest materials to make our products better.

Production cost and process improvement: We suggest the best production process for each customer, while keeping costs down and making sure the product is of high quality.

We promise to check our products thoroughly and make sure they are always delivered on time. This will help our customers meet their supply chain needs.

RUNTONG has a lot of experience in industry and has professional team members. This has made RUNTONG a trusted partner of many international customers. We always put our customers first, keep making our service processes better, and are dedicated to creating more value for our customers.

If you want to know more about RUNTONG's services or if you have any other special requirements, welcome to contact us!

Post time: Apr-17-2025