Insoles are essential products that combine functionality and comfort, catering to diverse demands across various markets. To meet the varied needs of our clients, we offer OEM pre-made product selection and Custom mold development.

Whether you aim to expedite time-to-market with pre-made selections or require mold customization for unique designs, we provide efficient and professional solutions tailored to your requirements.

This guide will introduce the features and suitable scenarios for both modes, along with a detailed analysis of material selection and production processes, empowering you to create high-quality insoles that meet market demands.

An insole OEM customization, we cater to clients' diverse requirements through two main modes: Pre-made Product Selection (OEM) and Custom Mold Development. Whether you aim for a quick market launch or a fully tailored product, these two modes can accommodate your needs. Below is a detailed comparison of the 2 modes

Features - Utilize our existing insole designs with light customization, such as logo printing, color adjustments, or packaging design.

Deal For - Clients looking to reduce development time and cost while testing the market or launching quickly.

Advantages - No mold development required, short production cycle, and cost-effectiveness for smaller-scale needs.

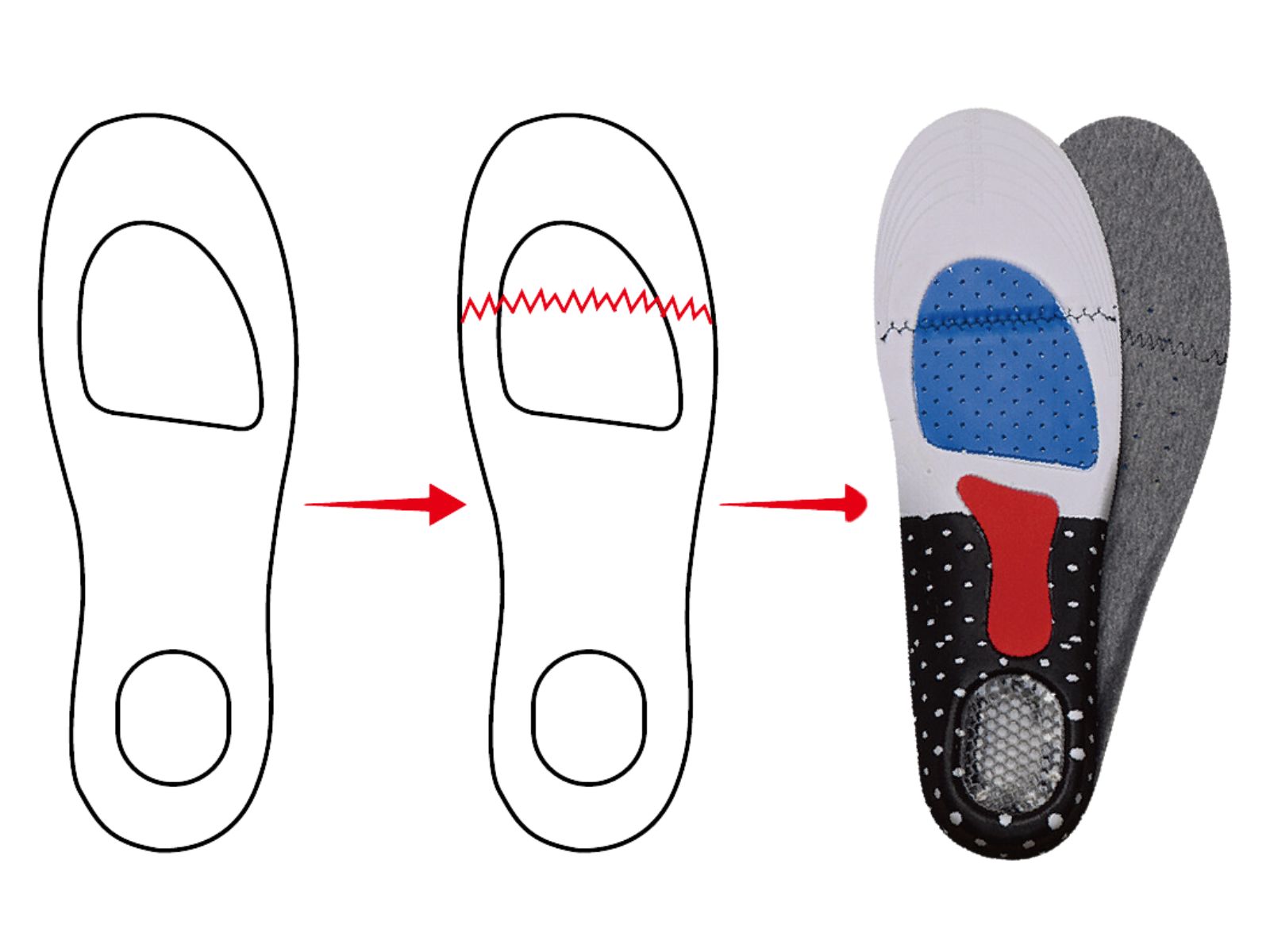

Features - Fully customized production based on client-provided designs or samples, from mold creation to final manufacturing.

Deal For - Clients with specific functional, material, or aesthetic requirements who aim to create differentiated brand products.

Advantages - Highly unique, designed to meet precise needs, and enhances brand competitiveness in the market.

With these 2 modes, we offer flexible and professional services to meet varying client demands efficiently.

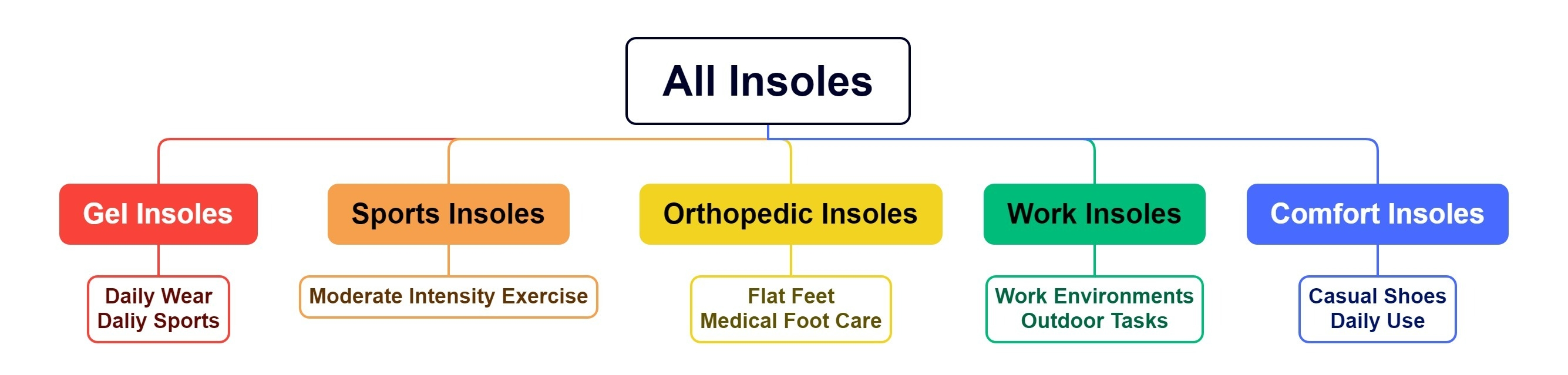

An insole OEM customization, the selection of styles, materials, and packaging is critical to product positioning and market competitiveness. Below is a detailed classification to help clients identify the best solutions.

Based on different use scenarios, insoles are classified into 5 main categories:

Special work insoles please check:

ANTISTATIC INSOLES: The Perfect Pairing with Safety Shoes to Ensure Workplace Safety

Based on functional requirements, we offer four main material options:

We offer 7 various packaging options to meet branding and marketing needs.

In insole OEM customization, we also offer a variety of additional services to meet personalized branding requirements:

Insole Pattern Customization

We support the design of insole surface patterns and color schemes based on client requirements.

Case Study: Customizing brand logos and unique design elements to enhance product recognition.

Example: As shown in the image, the branded insole features a unique gradient color design and brand logo.

Display Rack Customization

We design and manufacture exclusive display racks tailored to sales scenarios for showcasing insole products.

Case Study: Display rack dimensions, colors, and logos can be adjusted based on brand needs to suit retail environments.

Example: As illustrated in the image, custom display racks enhance brand visibility and optimize retail space utilization.

Through these additional customization services, we help clients achieve comprehensive support from product development to marketing, creating more opportunities for brand value enhancement.

When collaborating with high-quality clients, we always engage in in-depth communication with a professional industry perspective, helping clients identify market demands and unlock greater business value. Below is a case study involving a major retail client who invited us for an on-site product meeting:

The client was a large international retail chain brand with potential demand for insole products but no specific requirements.